After months of selecting every detail — alloys, coatings, thermal layers, and intelligent systems — your GreenBox™ is finally ready. Every weld and circuit serves a purpose; every surface, a function. Within its frame, an adaptive AI core manages structure, energy, and security with quantum-key precision. Crafted for high-end cargo conveyance, it both conserves and produces power, drawing from motion, vibration, and ambient conditions. As the cranes lift it from the dock, this is no ordinary cargo — it’s a self-securing hybrid energy platform, engineered to perform anywhere on Earth. What leaves the port is your design made real — disciplined, efficient, and alive.

With standardized dimensions and secure locking systems, ISO containers offer reliable protection for shipments.

GreenBox™ is a bespoke multi-modal ISO container — yes, it travels by ship, rail, air, or truck. But it’s also multi-modal in four operational dimensions: energy, intelligence, research, and protection.

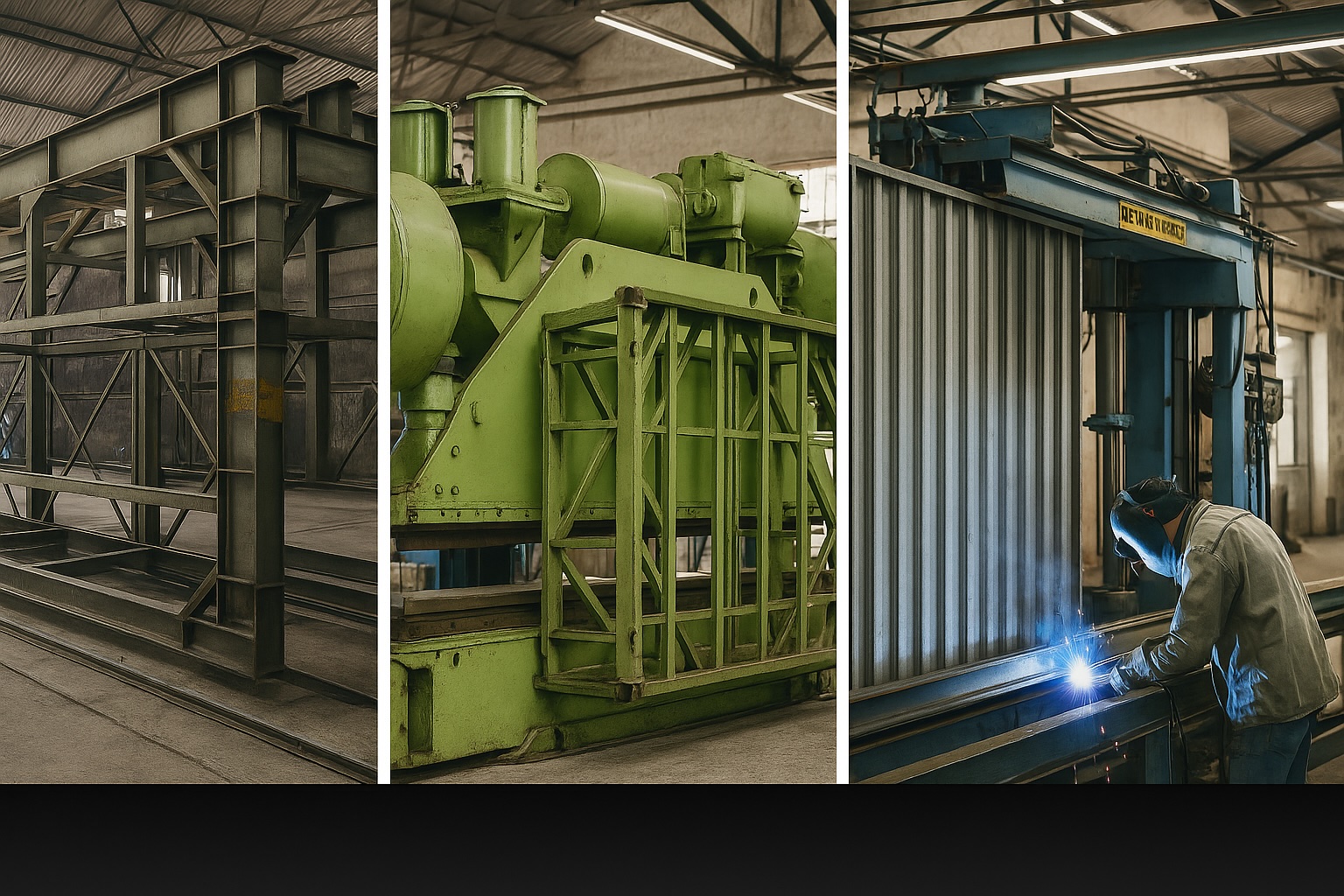

Every GreenBox™ is born from deliberate engineering, not automation. It’s built the way instruments once were — in a jig, tuned by hand, and aligned to thousandths. Inside that precision frame, advanced materials, entropic energy systems, and digital cognition work in unison. Strength and intelligence share the same skin.

GreenBox™ | Purpose-Built for Precision Cargo

GreenBox™ is designed for precision shipments — light in weight yet high in worth.

From advanced instruments and biomedical equipment to archival assets and fine materials, these cargos require continuous protection and traceable custody.

Every GreenBox™ integrates secure structural cores, environmental stabilization, and multi-layered location awareness, ensuring that valuable contents remain safeguarded, authenticated, and accounted for throughout transport.

It’s not about moving volume; it’s about preserving value.

Structural Foundation The GreenFrame™ uses uniform 6 × 6-inch folded-steel sections for all vertical columns and horizontal rails. Each plate of nano-steel is folded along a 45-degree interior rib and welded on the inner lip, producing a sealed, torsion-resistant profile. Columns and rails share this geometry, giving consistent strength and heat-transfer behavior throughout the frame.

Assembly Upper and lower rails are welded to four corner columns to form a rigid rectangular frame before any floor or roof assemblies are added. The lower front rail includes a small recess for trailer gooseneck clearance, reinforced locally to maintain beam strength. ISO corner castings are welded into each column end for stacking, and side castings at 8' and 10' intervals, enable adjoining GreenBoxes™ to lock together structurally, in parallel or perpendicular.

Protective & Functional Layers Every frame member receives multilayer protective finishes — corrosion primer, nano-ceramic topcoat, and antimicrobial sealant — and internal dielectric and thermal-control films that interface with GreenShield™ and GreenTransform™ systems. These inner coatings turn the structure into a controlled surface for both protection and thermal exchange.

When one starts rethinking our practice of moving heat into the atmosphere, and attracting it instead...

• Exterior Corrugated Nano-Steel Skin Functions as a high-surface-area collector, drawing in solar, atmospheric, and kinetic BTUs while maintaining structural strength.

• Graphene Oxide Coating Acts as the thermal and electrical coupling medium, instantly spreading and equalizing heat before it enters the exchanger network.

• Exterior Heat Exchanger Converts absorbed BTUs into fluid-borne energy, routing them through GreenTransform™ conduits for storage or redistribution.

• Aerogel & Composite Core Serves as a thermal gatekeeper and shock absorber, isolating gradients while converting blast or ballistic energy into controlled heat.

• Ballistic & Polyurea Shielding Provides impact resistance and mass-damping, ensuring that every absorbed joule of kinetic energy becomes usable thermal input.

• Viscoelastic Dampening & Interior Heat Exchanger Translate vibration and acoustic energy into BTUs, linking structural oscillation to the container’s thermal management loop.

• Radiation & EMP Shield Mesh Performs dual duty: protecting onboard electronics while scavenging electromagnetic energy into the entropy-harvest system.

• Interior Stainless Liner Completes the cycle with a reflective, sterile surface that retains harvested BTUs within the thermodynamic lattice.

Together, these layers form an energy-adaptive armor—a living material network that turns mechanical stress, radiation, and heat into the ordered flow that powers the GreenBox™ ecosystem.

Each GreenWall™ panel functions as both structure and sensor—its layered materials not only manage heat but interpret it. From nano-steel skin to graphene mesh, every component participates in a unified thermodynamic continuum that captures, transforms, and learns from energy in all its forms. The result is a living architecture that doesn’t merely resist the environment—it computes with it.

🜂 Result: A living surface where energy, vibration, and information coexist in equilibrium — every panel an entropy node, every node a contributor to the GreenBox™’s intelligent energy lattice.

Every GreenBox™ is equipped with dual GreenDoor™ assemblies, providing secure, independent access to the Service Bay and Cargo Bay compartments.

Each set of double doors is engineered for high security, integrating structural reinforcement with smart locking and traceability systems that operate throughout transport.

Independent Access Control: Service personnel and cargo handlers work through separate portals, preserving the isolation of mechanical and payload areas.

Electronic Locking System: Multi-factor encrypted locks authenticate users locally or through remote command, with full event logging for every access.

Global Traceability: Every GreenDoor™ assembly is tied into the GreenBox™ DigitalTwin™, recording identity, location, and condition for continuous oversight during global transit.

The result is a dual-compartment security architecture that upholds containment integrity, ensures operational separation, and maintains verifiable custody from origin to destination.

IIS GreenBox™: Revolutionizing Sustainable Cargo Shipping

The “IIS GreenBox” is a cutting-edge, intelligent intermodal cargo container designed to transport high-end shipments with unmatched security, precision, and environmental sensitivity.

Designed with advanced climate control, renewable energy systems, and smart monitoring technology, GreenBox™ is set to reduce energy consumption, minimizes reliance on fossil fuels, and captures excess thermal energy during transit.

Equipped with solar and cooling panels, graphene battery storage, advanced nano components and phase change materials (PCMs) for thermal management, the GreenBox™ is designed to not only protects valuable cargo but also significantly lower its carbon footprint. For unique usages, the container is designed to Beyond MIL Spec to protect its capabilities.

By reducing CO₂ emissions during transport, GreenBox™ may generate “carbon credits”, enabling tangible financial benefit while advancing sustainability goals. With an ability to generate credits through reduced energy use, renewable energy integration, and advanced climate control, organizations using IIS GreenBox™ may create an additional revenue stream through carbon markets.

For businesses looking to ship high-value goods while making a positive environmental impact, IIS GreenBox™ offers the perfect combination of “innovation”, ”sustainability”, and “financial efficiency”.

Each wall, roof, and floor panel becomes an instrument of physics.

Within these layers, entropy gradients—differences in heat, pressure, and vibration—replace electrons as the variables of logic.

The GreenBox™ doesn’t simulate the physical world; it computes within it, manipulating real thermodynamic states as informational constructs.

The phase-change cassettes inside GreenTransform™ behave as thermal memory cells—solid or liquid, latent or active—each holding and releasing information as enthalpy differences.

Here, computation is not metaphor but material: logic by controlled heat flow.

Even its sidewalls act as processors.

Each independent panel resonates within its own frequency band, sampling the environment through vibration and thermal exchange.

Slight variations among panels create a natural form of parallelism—a vibration-space array performing analog computation through interaction.

It’s distributed computing without silicon: a structure that senses, harmonizes, and thinks through resonance.

Because the GreenBox™ continuously harvests and reorganizes energy, its internal loops already reduce entropy—the same principle that defines information.

That makes it a natural platform for Landauer-limit studies, where the minimum energy cost of erasing a bit becomes a measurable, physical reality.

With its embedded sensors and controlled energy routing, a properly instrumented GreenBox™ could trace that boundary in real time—showing where information and thermodynamics truly meet.

In research configuration, a GreenBox™ offers what no conventional lab can:

a perfectly characterized geometry, a distributed sensing field, active heat routing through Transform™ modules, and multi-layer shielding that isolates pure thermodynamic behavior.

It is both the experiment and the apparatus—its own testbed, containment, and computational field.

That’s why we say GreenBox™ is more than a machine.

It is, quite literally, the world’s first macro-scale thermodynamic computer—a place where entropy is captured, ordered, and transformed into thought.

From Telegraph Lines to Quantum Skies

It began with a spark and a signal — copper lines stretched across continents, carrying the first pulses of human connection.

GreenConnect™ continues that legacy: communication through any medium, by any means necessary.

From rail telegraphs to orbital relays, each GreenBox™ inherits the same mission — to stay connected when nothing else can.

Today’s GreenConnect™ arrays replace wire and key with embedded, self-tuning antenna systems spanning myriad modes of communication — 3G to 5G, satellite, ionospheric, RF, and beyond.

If a signal can travel, a GreenBox™ should find it, lock onto it, and speak across it.

Connectivity isn’t an option; it’s engineered resilience.

GreenBox™ in Transit — Autonomous Functionality

When a GreenBox™ is in motion, it is not dormant freight — it is a live, self-regulating organism.

Each unit operates as an autonomous thermal and cognitive system, maintaining balance while adapting to the dynamics of travel by land, air, sea, or rail.

During transit, the GreenTransform™ network continuously captures and redistributes BTUs generated by motion, vibration, solar exposure, and ambient variation. These thermal exchanges stabilize cargo temperature and feed the container’s internal energy reservoir, allowing the system to power its own monitoring and communications arrays.

Meanwhile, embedded Dystance™ intelligence interprets vibration and entropy signatures as data, refining predictive models for route, motion, and cargo stability. Every shift in acceleration, roll, or gradient becomes part of a learned behavioral map, giving the GreenBox™ awareness of its own movement through the world.

As a result, each GreenBox™ travels not as passive cargo but as an active node — sensing, learning, and reporting. It safeguards its contents, optimizes its own internal environment, and maintains a constant cognitive and energetic link with its fleet companions.

In transit, the GreenBox™ is both vessel and mind: moving matter that knows it’s moving.

In time, every GreenBox™ finds its home. After years in motion—crossing oceans, carrying light, data, and ideas—it settles beside its companion, linking thought to thought, purpose to purpose. Together they form a Pod: a living organism of energy, intelligence, and design. Here, motion becomes meaning, and the journey turns into belonging.

When several Companion Sets gather, they form something greater—a living constellation of purpose-built Pods. Each Pod—whether for health, research, governance, or energy—extends the mind of the GreenBox™ into a collective intelligence, rooted in place yet connected to every other node across the O|Zone™ world.

"Among these Pods, HealthPort™ and ScanPort™ stand out—a living network of scanning and research facilities designed to incorporate Companion Containers, where human health and Digital Intelligence meet at the edge. Each Pod is powered by its own geothermal core and a lattice of cognitive engines—proof that intelligence, like life, thrives wherever energy and purpose align."

To some, a GreenBox™ is a container. To others, it’s a vessel of change—an instrument of creation moving across borders and generations. For those who recognize its rhythm, the journey does not end here. It continues in the circle of minds shaping what comes next.

Every journey leaves a trace, but only a few become a legacy. GreenBox™ is not built for the moment—it’s built for the continuum. For those who don’t wait for the future, they design it. One decision ahead of time.